Did you know that the secret to revolutionizing laboratory processes lies in the hands of a few innovative liquid handler distributors? These vital components can transform tedious tasks into seamless operations.

As laboratories face growing demands, the role of liquid handler distributors has become more crucial than ever. Their advanced technology promises to reduce human error, improve efficiency, and save time.

Surprisingly, many labs today still rely on outdated manual pipetting, risking cross-contamination and inconsistent results. But liquid handlers can process thousands of samples with unmatched accuracy, ensuring the integrity of experiments. And yet, the true potential of these distributors remains vastly untapped… But that’s not even the wildest part…

Contrary to widespread belief, automated liquid handlers aren’t just for large, well-funded institutions. Companies of all sizes stand to gain from this tech revolution, often recouping initial investments quickly. These tools reduce manual workload, lower error rates, and optimize the entire workflow. And just when you think you've grasped their impact, you'll discover another layer to this technological marvel…

What happens next shocked even the experts…

When considering liquid handlers, the focus is often on upfront costs. However, ongoing maintenance and software updates can significantly impact the total cost of ownership. A single software update might require substantial downtime, affecting lab productivity. But here’s a twist: some distributors are now offering seamless, real-time updates to keep operations running smoothly.

Many labs remain unaware of the true long-term savings provided by liquid handler distributors. Automated systems can lead to a reduction in labor costs and increased throughput. The added value becomes evident when considering the reduction in human resource allocation to mundane tasks. And here’s the clincher: enhanced accuracy minimizes costly experimental errors.

Insider tip: smart labs leverage tech support included in distributor packages to mitigate unexpected costs. This foresight prevents budget overruns and ensures a smooth workflow. This strategy often stays under the radar in broader cost-benefit analyses.

But there’s one more twist: some of these distributors are innovating with subscription-based models, offering labs flexible, scalable options. What you read next might change how you see this forever.

Small labs often assume that sophisticated lab automation is out of reach, reserved for top-tier institutions. Yet, the emergence of budget-friendly options is reshaping the landscape. Entry-level liquid handlers now offer capabilities previously only found in high-end models.

These tools enable smaller labs to reduce labor-intensive tasks, achieving precision parallel to major research centers. Startups and academic labs are leveraging these advancements to compete on equal footing, breaking previous barriers driven by cost constraints.

Interestingly, many distributors now cater to these niche markets with innovative leasing options. This approach allows smaller setups to access top technologies without hefty initial investments, democratizing advanced lab tech.

But here’s a twist you might not expect: sharing systems between institutions is becoming a growing trend, maximizing utility and reducing individual costs. This collaborative approach upends traditional barriers in unexpected ways.

There's more to the efficiency gains from liquid handlers than meets the eye. Aside from reducing manual handling, these tools also permit parallel processing, where multiple tasks are executed concurrently. This multitasking capability drastically shortens the timeline for completing complex experiments.

Quality control is enhanced, as liquid handlers ensure uniformity in sample preparation. This precision eliminates variability, producing more reliable results, which is of paramount importance in sensitive experiments requiring high reproducibility.

Liquid handler distributors are now championing eco-friendly models, reducing the carbon footprint of labs by minimizing waste through precision dispensing. Lesser waste also means significant savings in material costs.

The enhanced data integration with lab management systems creates a seamless transition between experimental set-up and data analysis. But wait until you hear how these systems adapt to future tech advancements.

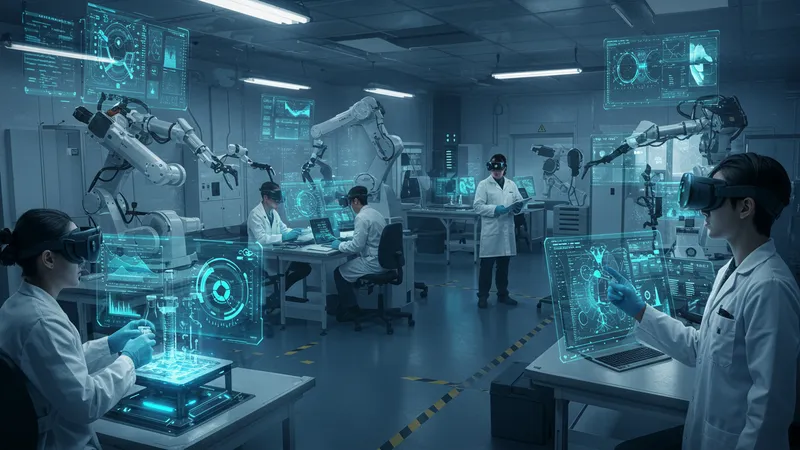

The progressive compatibility of liquid handlers with AI and machine learning tools is setting a new benchmark. Labs that integrate these two innovations find themselves at the cutting edge of scientific research.

AI-assisted liquid handlers can predict the optimal settings for experiments, refining processes before actual execution. This not only maximizes efficiency but allows for enhanced experimental outcomes with minimal human intervention.

Distributors are working towards perfect harmony between hardware and software, enabling complex analyses directly from the liquid handler interface. This seamless integration supports more nuanced investigations, pushing the boundaries of scientific discovery.

But here’s a compelling hypothesis: the potential for predictive maintenance, where AI forecasts equipment failures before they occur, saving untold resources in repairs and downtime. And there’s even more innovative flair in how this revolution unfolds.

Human error has always been a latent risk in manual lab processes. Of particular concern is the possibility of contamination or mislabeling that can derail significant research projects.

Automated liquid handlers offer a solution, ensuring that each step in the procedure is precisely controlled and executed. They operate under strict protocols set by lab staff, yet free from individual variability.

Moreover, these devices provide traceability for every action. This feature facilitates a new level of trust and verification, crucial during audits or peer reviews where transparency is critical.

Believe it or not, the return on investment in automated systems due to error reduction alone justifies the initial expense for many laboratories. But there’s an even bigger payoff when it comes to efficiency.

One of the significant traditional lab challenges has been the inability to scale up experiments quickly. Automation with liquid handlers allows for precision scaling without added complexity.

From drug development to genetic sequencing, these tools ensure that larger volumes or more complex series do not compromise the integrity of results. Labs can now pursue ambitious projects that require extensive trials without increased logistical strain.

Surprisingly, these advancements offer a solution to workforce issues, handling increased workloads with limited staff. This development democratizes high-level research across institutions of varying sizes.

But the kicker here is in how the renewed focus on throughput aligns with futuristic applications, all without overwhelming resources. Stay tuned for the life-saving implications of these applications.

In fields like pharmacology and medicine, every second counts. The ability to prepare and process multiple samples simultaneously accelerates lifesaving research, crucial in pressing scenarios like pandemics.

As public health crises demand swift response, liquid handlers allow for rapid testing and development of solutions. Improving throughput without sacrificing accuracy is vital in producing reliable, scalable treatments.

Furthermore, advancements in personalized medicine rely heavily on precision infrastructure. Liquid handlers enable tailored treatment strategies, performing necessary analyses to usher an era of medicine where interventions match individual patient profiles.

While many might believe this technology is far off, the truth is it's already reshaping modern medicine. But that realization opens another frontier in coordination and collaboration between labs.

Connectivity and shared protocols are bridging the gap between global research efforts, leading to groundbreaking collaborative projects. Liquid handlers become the technical backbone facilitating shared data and methodologies in these endeavors.

With systems able to integrate seamlessly, protocols developed in one part of the world can be quickly adopted elsewhere. This global coordination fast-tracks innovation, allowing adaptation worldwide faster than ever before.

Real-time data exchange between institutions, facilitated by these tools, enhances transparency from lab bench to scientific publication. Ensuring consistency and communication enhances trust, critical in high-stakes research environments.

However, there's a rising demand for even greater collaboration, beyond data - shared human resources and facilities provide an unexpected edge. What lies ahead will redefine the very nature of scientific cooperation.

The push towards sustainable science finds an ally in modern liquid handlers. These devices have reduced the amount of reagents and energy used in everyday operations, contributing positively to the environment.

Laboratories striving for a reduced carbon footprint find these tools invaluable, as they use fewer plastics and power. Automated liquid handlers cleverly optimize fluid volumes, reducing waste significantly compared to manual processes.

Moreover, with extended lifecycle designs, the demand for replacement components and units dwindles, furthering the commitment to sustainability in scientific research.

This contribution to reducing environmental impact fortifies the argument for their widespread adoption in environmentally-conscious setups. But there's yet another dimension to this green revolution worth exploring.

Concerns often circle around the impact of automation on employment. Skeptics argue it displaces skilled workers, while proponents highlight the shift towards higher-level roles.

Automation frees lab personnel from repetitive tasks, freeing skilled minds to engage in more meaningful research and analysis. Investing in workforce training and specialization avenues fortifies a solid foundation for these transitions.

There's a profound realization among advanced institutions: automation is not replacing the workforce, but transforming it. This change in dynamics presents an opportunity for the upward mobility of talent within labs.

The intersection of skilled human resources with advanced technology not only drives productivity but fosters an environment ripe for innovation. What unfolds redefines conventional perceptions of employment and collaboration.

Collaboration across borders presents its hurdles—cultural differences, language barriers, and differing regulations. However, shared usage of technology smoothes these barriers over time.

Global standardization provides a common language, ensuring seamless transitions and operations across international borders. The shared technical language sets a foundation for robust communication strategies, enriching scientific discourse.

The story of automated liquid handler dispersal ensures equal technological accessibility worldwide, fostering inclusive scientific communities dedicated to shared goals.

This collaboration heralds an age when science transcends denomination and borders, united in a mission for greater human understanding and health. But the true culmination must tie it to the next frontier of lab innovations.

With quantum computing and cutting-edge AI on the horizon, the synergy between liquid handlers and these technologies holds extraordinary potential. Labs capable of such integrations could unravel complexities previously deemed unsolvable.

Continual investment in R&D by distributors guarantees a pipeline of new, groundbreaking tools. As more data from liquid handlers is utilized to develop algorithms, expect a feedback loop further enhancing both handler efficiency and AI performance.

This marriage of technologies will open applications far beyond current limits, guiding the next wave of innovation across fields such as genomics, materials science, and beyond.

The anticipated ripple effects across linked industries project an exciting future wherein human potential meets technological prowess. The revelations continue to shock as each piece aligns into a larger picture.

Throughout this journey, it's clear that liquid handler distributors offer revolutionary potential that spans cost-saving, time efficiency, error reduction, sustainability, and global cooperation. These factors blend to create transformative outcomes for laboratories worldwide.

Boldly embrace the advent of this technology, ensuring your laboratory capitalizes on innovations that not only enhance scientific precision but break through historical barriers. Now, with informed insight, take action to explore these tools firsthand.

Encourage your peers to delve into this subject—to understand the untapped possibilities and forge collaborations that transcend traditional research boundaries. Share this revelation with your network: the unfolding future of laboratory automation awaits.